MANAGING THE WORKORDER MANAGER (DISMANTLERS MANAGER GUIDE)

MANAGING THE WORK ORDER MANAGER

GENERAL GUIDE

THE KEY IS TO CREATE EFFICIENCY -ITS A SALES PRODUCTION LINE

Don't check it every 5 minutes ,sort work order manager at stage day then check back at most every 30 minutes ,at MOST ideally we only check every hour

Don't touch items twice ,once you see and act ,do it in one process ,i.e sick act/allocate or set as car or do yourself ,do see 1/2 act assign to yourself then do again later

When you see new item in your view search from sales screen

DO WE PICK THE PART OR DO WHOLE WHOLE CAR ?

make decision as to whether to dismantle complete car at that time or just remove the part

almost always if car is scrap car we dismantle the whole car at that time

absolutely always if car is scrap car and car has to be moved by forklift then we dismantle the whole car at that time

if car is keep car and we can easily remove item (i.e door mirror,bonnet ) in less 15 minutes we may decide to just remove that item )

if item can be removed in less 15 mins and work order manager is booked out for that day then we will just remove the part and not dismantle the whole car

then dismantler manager checks car to confirm how difficult part is to remove and either ,

--just picks up part himself i.e if just sitting in car

decides to dismantle and scrap the car completely at the same time (inventory manager will assist with print out )

decides to remove this sold part but keep the car

------------------------------------------------------------------------------------------------------

IF SOLD PART WILL NOT BE REMOVED BY DISMANTLERS ON TIME

If item will be late Operations manger to find out when part will be actually ready ,

If item is late dismantler tells operations manger ,they don't directly tell sales person

Operations manager informs sales staff of when part will be ready

Operations manager puts resolution note on the item in work order manger i.e "item late will be ready 2pm"

Item stays in dismantling view on work order manger (so operations manager has view of item

Ideally this is done before the item actually is overdue on work order manager

-------------------------------------------------------------------------------------------------

Sales staff contact customer if required and select alternate courier and or day for shipping on w/o

Sales staff advise operations manager of new carrier details

If order now cancelled sales kills the work order and advises operations manager

THE KEY IS SALES SETTING REALISTIC TIMES FOR THINGS TO BE DISMANTLED ,(READ THE WORK ORDER MANAGER ) AND COMMUNICATION

Sales should respond to operations manager within 30 minutes of receiving message ,if they don't then operations sends message again

If still no answer after 30 minutes then operations manager physically goes into sales office

-------------------------------------------------------------------------------------------------

priority is given to rescheduling so we don’t lose any sales ,if we are going to lose sales then lose the low value items ,then the low value customers (wholesale, private)

--------------------------------------------------------------------------------------------------------------- MISSING PARTS

operations/dismantling manager

If Part sold cant be found by shipping ,

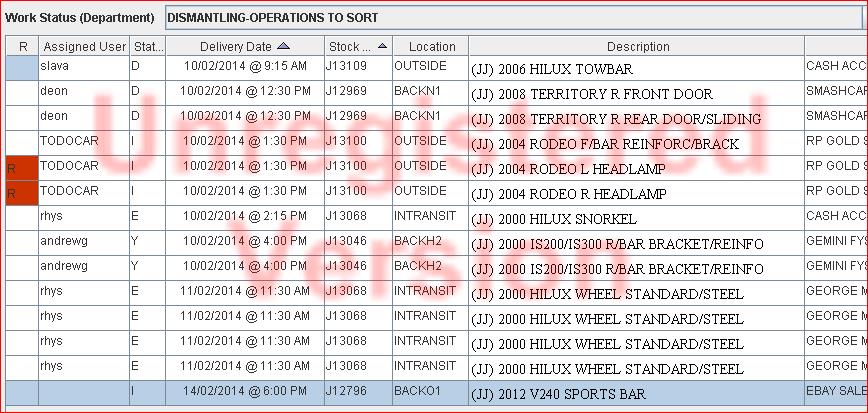

Shipping staff change views to DISMANTLING OPERATIONS TO SORT

OPERATIONS See the workorder in their view

missing parts are the responsibly of person as nominated on operations tasks table

-always check for alternate parts when first part is missing

For operations ,how do they know part is a missing part and thats why it is on work order manager ?

if part cant be found and no suitable alternative is available inventory manager

puts part in resolution with story that it is missing

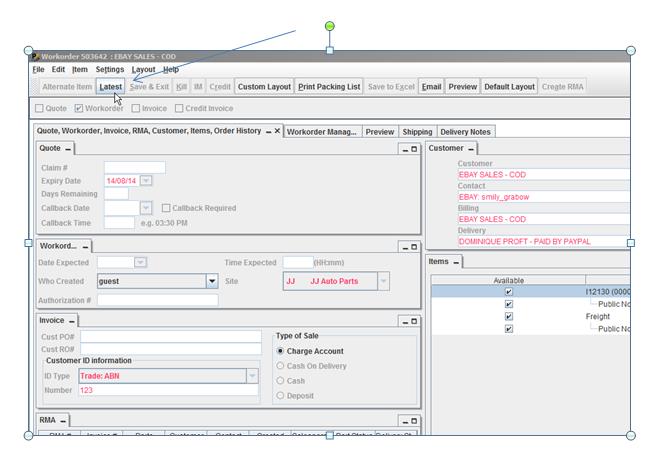

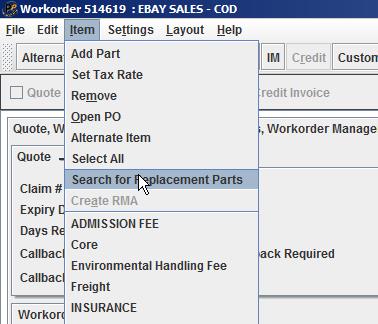

To do this from work order manager

select latest

THEN SELECT ITEM AND ,SEARCH FOR REPLACEMENT PARTS

From this screen you can put it into resolutions

Then change work order department to problem sales to sort ,

messages sales by pinnacle chat to inform them that part is missing and we don't have alternative available

it is then responsibility of sales person to cancel order/broker item or what ever

it is responsibility of operations to sort inventory

------------------------------------------------------------------------------------------------------

DAMAGED PARTS-

i.e part is sold off car or off shelf and its too damaged at all to be accepted by customer

firstly if maybe customer will take just check with sales staff before you make any assumptions ,maybe take photo on phone and email it to them ? (by emailing photo saves sales person walking 100m away from phones and also they can email these images to their customer )

if customer wont take and we dont have alternatives

then dismantling manager

puts part in resolutions as per guide above

moves work order on work order manager to sales problem sales to sort

message sales person with details

-------------------------------------------------------------------------------------------------

EBAY/ONLINE SALES

If you have issue with online or ebay sales then contact person is the JJ online sales manager please inform them and they will action as required

please note they wont be the person whose name is on work order ,we have various staff doing online sales but you have a single point of contact

------------------------------------------------------------------------------------------------------------------

OPERATIONS -IF YOU SEE THE WORK ORDER MANAGE IS OVERFULL

i.e you cannot accept any more dismantling orders that day

1.we prioritize the high value sales ,if we are going to lose a sales cause we are late then make it a $90 part not a $2000 engine

2.we prioritize for trade customers (not wholesales and not private)

inform the sales staff (send general email to all sales staff) ,its just communication

i.e

hi guys

the dismantling work order manager is full and we wont be able to start any new tasks that require car to go on hoist for the next 24 hours

we wont be able to do start any new small parts dismantling jobs till 3pm today

please note the guys are going as hard as they can ,thank for your patience

-------------------------------------------------------------------------------------------------------------------------------------------------

ACCOUNTABILITY WORK ORDER MANAGER

WHO IS CURRENTLY RESPONSIBLE FOR THIS TASK? THE WORK ORDER MANAGER DEFINES THIS

the work order manager clearly defines who is responsible for the order at that time ,

once its allocated to dismantle they are responsible

once its moved to pick parts then shipping is responsible ,it saves the confusion of ,"i thought you were doing that ..."

the item on the work order manager in dismantling dept are only are those orders that the dismantling dept are responsible for

once we are waiting to sales to action we move in problem sales to sort

once we are waiting for shipping we move into their dept

if we do move into sales problem to sort then make sure we notify sales staff of this

TIPS

make sure you understand and know exactly which part is sold ,if unsure check with the sales person

check vehicle location if its WEST SIDE OR EAST SIDE it has almost always already been dismantled (you can also look at parts location from MVR)

if car is "out front" or outside then its input but not dismantled yet

if we have sold parts off cars already dismantled before you give job to dismantler check that part is there and in good condition ,at times if car has been "picked from " many times we may decide at that point to dismantle and scrap the whole car ,we will use remaining parts report to decide which parts to take off at that point ,see separate article as regards this

-inspect the work area

when handing out tasks /checking progress -check scrap car area

cat converters or batteries in cars - if issue then responsible dismantler fixes

PARTS SOLD OFF CARS NOT INPUT YET "IN TRANSIT"

It is sales persons responsibility to make sure car is here before they sell item on work order and it is sales persons responsibility to make sure part is in salable condition before they add to work order manager

if car is "in transit " then its either out front and not dismantled or maybe not even here yet , sales to add extra 24 hours to the processing time for these sales

there will be "one off/rush jobs " and that's fine but if we continually are having "exceptions " to the system then this effects our efficiency and ability to be price competitive and sustainable.

---------------------------------------------------------------------------------------------------------------------------

OPERATIONS PICKING ALTERNATE ITEMS

Its ok for operations to pick alternate item and not tell sales ,except when

-ebay sale of panel item that is colored (tell JJ ebay sales manager so they advise customer )

-if jj sales has specifically said on work order to pick certain item or color

-alternate item is off less condition/quality

-for non oem items ,the replacement item would generally have to be the same ,if unsure check with sales

-for mag wheels ,the alternate item is of similar or better condition ,be careful with tyres etc ,once again if unsure communicate with sales

-for engine and trans ok to do ,just inform sales what you are doing

in all cases operations will be the one that selects the alternate and puts the first one into resolutions etc not the sales guys

----------------------------------------------------------------------------------------------------------------------------------

WORK ORDER MANAGER VIEW SETTINGS

FOR OPERATIONS/DISMANTLING MANAGERS/DISMANTLERS

SORTED BY - DELIVERY TIME (LARGE TRIANGLE ) ,THEN STOCK NUMBER (SHOWS IF 2 ORDERS OFF SAME CAR)

1.The resolutions -be aware of the extra warning notes

2.assigned user -this tells me if its done or not

3.status -quickly tells eur whose job to do

4.delivery date -when does the buyer expect it done by

5.stock number -shows me if multiple items off the same car ,or different orders off the same car

6.Location-helps me batch the checking if required

Sales person -no need to have on left ,operations treats them all the same except that for new sales staff we might double check their work sometimes

Customer -it doesn't matter except we prioritize trade sales

---------------------------------------------------------------------------------------------------------------------------------------

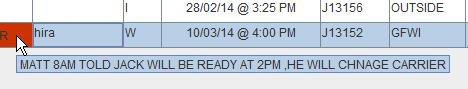

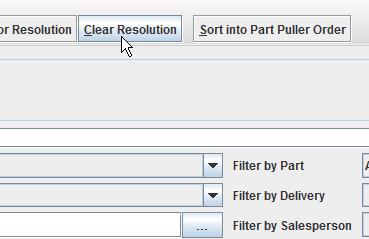

USING THE RESOLUTIONS FIELDS

We use the resolutions fields to add extra one off notes as regards an order so other staff understand the status quickly

when we add message we must communicate clearly so other staff know the -WHO/WHAT/WHY/WHEN AND HOW of the message

so when adding message ,note

who wrote the message

when

to whom (if its not obvious)

whats required/next steps

i.e

CLEAR RESOLUTION

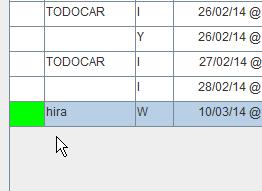

once the message is action ed by the next party then they can "clear the resolution " this makes resolution go green which shows required action has been done

Type in your action as to why you are clearing

once this is saved resolution field will now be green

Related Articles

Dismantlers /Operations staff -using the work order manager

The work order manager helps the company manage the dismantling flow if items we have sold VIEW THE VIDEO HERE we need to effectively communicate and understand --who is responsible for item at that time (whom is it assigned to ) --what is status of ...WORK ORDER MANAGER GENERAL GUIDELINES

we use work order manage to manage sold parts that have to be dismantled background scrap cars - these cars we only remove the high value parts and then scrap the hulk/body shell keep cars - after removing engine/major parts we keep the hulk on side ...MANAGING WORK ORDERS - OPERATIONS STAFF GUIDE UPDATED 06/10/2021

WHY? We do this so we don't miss any issues that needs action. OPERATIONS STAFF will use the work order manager so they can view all orders as they are process thru the different production departments OPERATIONS STAFF can view and update with any ...WORKORDER MANAGER VIEWS

WORK ORDER MANGER VIEW SORT COLUMNS W/O STATUS -Have the completed at the top so can clear out Delivery Date Order number -so orders togetherMANAGING WORK ORDERS -SHIPPING STAFF GUIDE UPDATED 06/10/2021

Link guide to doc